Nekuda kwehunhu hwecpvc raw material, screw, barrel, die mold, kudhonza-off uye cutter dhizaini inosiyana neupvc pombi extrusion line.

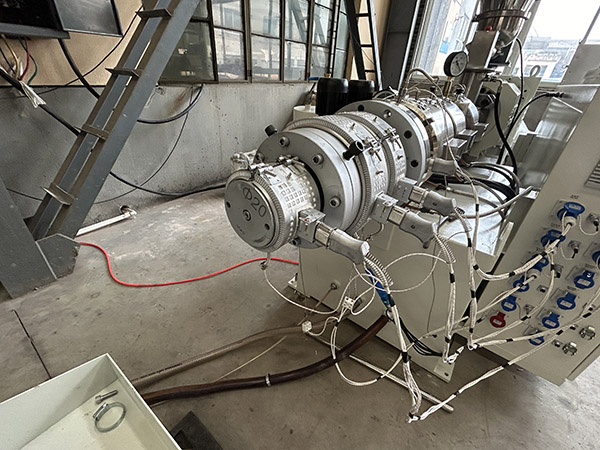

Nhasi ngatitarisei pane screw uye kufa mold dhizaini.

Maitiro ekugadzirisa screw dhizaini ye cpvc pombi extrusion

Kugadzirisa screw dhizaini yeCPVC pombi extrusion inosanganisira zvigadziriso kukwirisa kunyungudika, kusanganisa, uye kufambisa kwezvinhu zveCPVC. Heano mamwe maitiro ekugadzirisa screw dhizaini:

1. **Screw Geometry**:

-Gadzirisa kudzika kwendege uye kukwirira: Kugadzirisa kudzika kwendege uye kukwirira kunogona kukwidziridza kutakura uye kusanganisa kweCPVC zvinhu mukati meiyo screw chiteshi.

2. **Compression Ratio**:

- Wedzera iyo yekumanikidza reshiyo: CPVC yepamusoro yakanyunguduka viscosity ingangoda yakakwirira compression ratios kuti ibudise yakakwana kudzvanywa uye shear yekunyungudusa nekusanganisa.

3. **Screw Material uye Coating**:

-Shandisa machira kana machira ane akakwidziridzwa kupfeka kuramba uye kusaita ngura kumirisana neabrasive uye corrosive nature yeCPVC kugadzirisa.

- Funga machira kana marapirwo anoderedza kupokana uye kunatsiridza kuburitsa zvivakwa kuti uwedzere kuyerera kweCPVC kunyungudika uye kuderedza screw kupfeka.

4. **Screw Cooling/Heating**:

- Shandisa kupisa / kutonhora nzvimbo padivi pescrew barrel kudzora tembiricha yekunyungudika uye viscosity, kunyanya munzvimbo idzo CPVC inogona kusangana nekupisa kwekupisa kana kupisa.

5. **Screw Cooling**:

- Ita shuwa kutonhora kwakaringana kutonhora kuchengetedza tembiricha kutonga uye kudzivirira kuwandisa kweCPVC kunyunguduka, kunyanya mune yakakwirira-kumhanya extrusion maitiro.

Nekutarisisa zvinhu izvi uye nekugadzirisa kwakakodzera dhizaini yekukurisa, vagadziri vanogona kukwidziridza CPVC pombi extrusion maitiro kuti vawane inofanana kunyungudika mhando, homogeneity, uye throughput.

Maitiro ekugadzirisa dhizaini ye cpvc pombi extrusion

Kugadzirisa dhizaini yeCPVC pombi extrusion inosanganisira zvigadziriso kuti zvigadzirise CPVC yepamusoro yakanyunguduka viscosity uye ive nechokwadi yunifomu extrusion.

1. **Die Heating/Cooling**:

-Gadzirisa kupisa / kutonhora nzvimbo: CPVC yakakwirira yekugadzirisa tembiricha inogona kuda kugadziridzwa kune inofa yekudziya / kutonhora sisitimu kuti ichengetedze tembiricha yakafanira uye kudzivirira kupisa kana kutonhora.

2. **Die Materials uye Coatings **:

- Funga nezvekushandisa zvinhu / machira ane yakakwirira kupisa kupisa: CPVC yakakwirira yekugadzirisa tembiricha inogona kudikanwa zvekufa kana machira anogona kumira tembiricha yakakwira pasina kushatisa.

3. **Die Surface Pedzisa**:

- Ita shuwa kuti yakapfava uye yunifomu inofa pamusoro pekupedzisira: Iyo yakatsetseka yekufa pamusoro inobatsira kuderedza kukweshera uye kugera masimba, kuderedza njodzi yekunyunguduka kutyoka uye kuve nechokwadi cheunifomu extrusion.

4. **Flow Control Devices **:

- Batanidza zvigadziriso zvekudzora kuyerera, senge zvinopinza kana zvinodzora, kukwirisa kuyerera kugovera uye kumanikidza kufanana pane inofa mbiri, kunyanya mune yakaoma die geometries.

5. **Die Design Simulation**:

-Shandisa die dhizaini simulation software kuongorora mafambiro ekuyerera, kudzvanywa kugovera, uye tembiricha profiles mukati mekufa. Izvi zvinobvumira kuyedzwa kwechokwadi kweakasiyana ekufa magadzirirwo kuti agone kuita basa risati raitwa.

Nekutarisisa zvinhu izvi uye nekugadzirisa kwakakodzera dhizaini yedhizaini, vagadziri vanogona kukwidziridza CPVC pombi extrusion maitiro kuti vawane hunoenderana mhando uye dimensional kurongeka.

Mune extrusion process ye cpvc pombi, iyo mapoinzi anofanira kungwarira

Munguva yeextrusion process yeCPVC (Chlorinated Polyvinyl Chloride) pombi, akati wandei mapoinzi anoda kunyatsotariswa kuti ave nechokwadi chekugadzirwa kwepombi dzemhando yepamusoro. Hezvino zvimwe zvakakosha:

1. **Kubata Kwezvinhu uye Kusanganisa **:

- Ita shuwa kubata kwakakodzera uye kusanganiswa kweCPVC resin uye zvinowedzera kuti uwane yunifomu kupararira uye kuenderana mune izvo zvinyorwa. Kusanganisa kwakaringana kwakakosha kuchengetedza zvimiro zvinodikanwa zveCPVC komputa.

2. **Temperature Control**:

- Tarisa uye udzore tembiricha yekuwedzeredza nekungwarira, sezvo CPVC zvinhu zvine chaiwo tembiricha zvinodiwa pakugadzirisa. Chengetedza tembiricha mukati meyakakurudzirwa renji kudzivirira kushatiswa kwezvinhu uye kuve nechokwadi chekunyungudika kwakaringana kuyerera.

3. **Screw Design uye Magadzirirwo **:

-Shandisa extruder screws yakagadzirirwa zvakananga kugadzirisa CPVC zvinhu. Iyo screw dhizaini inofanirwa kupa yakakwana musanganiswa uye homogenization yekunyunguduka uku ichideredza kupisa kweshear kudzivirira kuparara kwezvinhu.

4. **Die Design uye Calibration **:

- Ita shuwa kuti dhizaini yakanakira CPVC pombi extrusion, ine zviyero zvakaringana uye geometry kugadzira mapaipi ane hunoenderana madziro ukobvu uye dhayamita. Chengetedza kufa zvakanaka kuti uwane yunifomu pombi zviyero.

5. **Kutonhodza uye Kudzima**:

-Simbisa inoshanda kutonhora uye kudzima masisitimu kuti ikurumidze kutonhodza iyo extruded CPVC pombi uye kuseta zviyero zvayo. Kutonhodza kwakakodzera kwakakosha kudzivirira kubvongodza kana kukanganisa kwepombi uye nekuona kugadzikana kwedimensional.

6. **Kudhonza nekuyera**:

-Dzora kumhanya kwekudhonza uye saizi yeCPVC pombi kuti uwane zviyero zvaunoda uye kupera kwepamusoro. Kudhonza kwakaringana uye saizi kunovimbisa kufanana mupombi dhayamita uye ukobvu hwemadziro mukati mehurefu hwepombi.

7. **Kuongorora uye Kudzora Hunhu**:

- Shandisa yakazara yekutarisa uye yemhando yekudzora sisitimu yekuona chero kukanganisa kana kusawirirana mumapombi eCPVC akawedzera. Ita ongororo yenguva dzose uye bvunzo kuti uone kutevedzera zvakatemwa uye zviyero.

Nekunyatso gadzirisa mapoinzi aya panguva yeextrusion process, vagadziri vanogona kugadzira emhando yepamusoro CPVC mapaipi anosangana nezvinodiwa zvinodiwa uye maitiro ekuita.

Nguva yekutumira: Kubvumbi-02-2024