1. Screw speed

Munguva yakapfuura, nzira huru yekuwedzera kubuda kweextruder yaiva yekuwedzera dhayamita ye screw. Kunyangwe kuwedzera kwescrew dhayamita kuchawedzera huwandu hwezvinhu extruded pane imwe unit nguva. Asi extruder haisi screw conveyor. Pamusoro pekuburitsa zvinhu, screw inoburitsawo, inosanganisa uye inogera epurasitiki kuti iite purasitiki. Pasi pemamiriro ekugara ari screw speed, kusanganisa uye kuveura kwescrew ine dhayamita yakakura uye yakakura screw groove pane izvo zvinhu hazvina kunaka senge screw ine dhayamita diki. Naizvozvo, maextruder emazuva ano anonyanya kuwedzera huwandu nekuwedzera screw speed. Iyo screw speed ye common extruder ndeye 60 kusvika 90 rpm kune echinyakare extruders. Uye ikozvino yave yakawedzera kuwedzera kusvika 100 kusvika 120 rpm. Yepamusoro kumhanya extruder inosvika 150 kusvika 180 rpm.

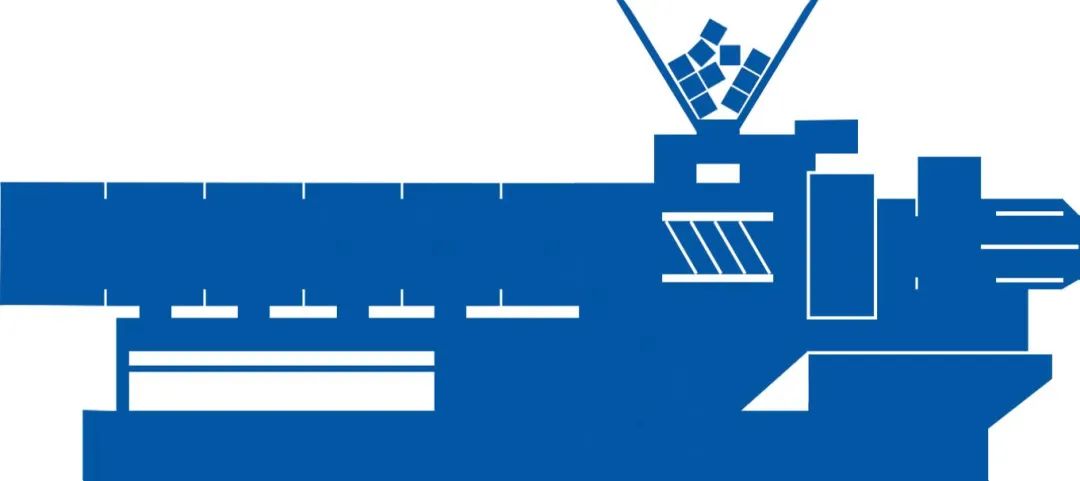

2. Screw structure

Iyo screw chimiro ndicho chinhu chikuru chinokanganisa kugona kweiyo extruder. Pasina inonzwisisika screw chimiro, kuyedza kungo wedzera screw kasi kuti uwedzere extrusion kugona kunopesana nemutemo wechinangwa uye hazvizobudirira. Iyo dhizaini yekumhanyisa uye yakakwirira-yekushanda screw yakavakirwa pahupamhi hwekutenderera kumhanya. Iyo plasticizing mhedzisiro yerudzi urwu rwe screw ichave yakashata nekumhanya kwakaderera, asi iyo plasticizing mhedzisiro inovandudza zvishoma nezvishoma kana screw speed yawedzerwa, uye yakanakisa mhedzisiro ichawanikwa kana dhizaini yekugadzira yasvika. Panguva ino, ese ari maviri epamusoro kugona uye akakodzera epurasitiki mhedzisiro inowanikwa.

3. Gearbox

Mutengo wekugadzira weinodzikisira wakada kuenzana nehukuru hwayo uye huremu, chero chimiro chakafanana. Hukuru uye huremu hwegiya bhokisi zvinoreva kuti zvimwe zvinhu zvinodyiwa mukugadzira uye mabhengi anoshandiswa akakura, izvo zvinowedzera mutengo wekugadzira. Panyaya yekubuda kweyuniti, iyo yakaderera mota simba uye huremu hwakaderera hweiyo giya bhokisi reyepamusoro-soro inoshanda extruder zvinoreva kuti mutengo wekugadzira pane imwe unit inobuda yeakakwira inomhanyisa extruder yakaderera pane iya yakajairwa extruder.

4. Motokari

Kune imwechete screw dhayamita extruder, iyo yekumhanyisa yakakura uye yakanyanya kunaka extruder inoshandisa simba rakawanda kupfuura yakajairwa extruder, saka zvinodikanwa kuwedzera mota simba. Munguva yekushandiswa kwakajairika kweiyo extruder, iyo mota drive system uye yekudziya uye kutonhora system inogara ichishanda. Iyo yakafanana sikuruu dhayamita extruder ine mota hombe inoita kunge ine nzara yemagetsi, asi kana ikaverengerwa nekubuda, iyo yekumhanya kwazvo uye yakakwirira kunyatsoshanda extruder inowedzera simba kupfuura yakajairika extruder.

5. Vibration damping matanho

High-speed extruders inowanzoitika kukudengenyeka, uye kunyanya kudengenyeka kunokuvadza zvikuru kune kushandiswa kwakajairwa kwemidziyo uye hupenyu hwebasa rezvikamu. Naizvozvo, matanho akawanda anofanirwa kutorwa kudzikisa kuzunguzika kweiyo extruder kuitira kuti uwedzere hupenyu hwebasa remidziyo.

6. Zviridzwa

Iko kugadzirwa kwekushanda kweextrusion ibhokisi dema, uye mamiriro ari mukati haaonekwe zvachose, uye anogona chete kuratidzwa kuburikidza nezviridzwa. Naizvozvo, chakanyatsojeka, chakangwara uye chiri nyore-kushanda chiridzwa chichaita kuti tinzwisise zviri nani mamiriro ayo emukati, kuitira kuti kugadzirwa kugone kuwana nekukurumidza uye zvirinani mhedzisiro.

Nguva yekutumira: Mar-01-2023